Birth of the Railway Locomotive

, 16 May 2020

Before the invention of the railway locomotive, the speed and pulling power of horses represented the maximum that land transport could achieve. Steam-hauled railways introduced entirely new concepts of speed; vastly more goods and people could be transported further, faster and more cheaply.

Steam-hauled railways revolutionised many aspects of peoples’ lives. Within less than a single lifetime, steam-hauled railways went from remarkable novelties to being mainstays of everyday life.

The railway revolution began in Merthyr Tydfil on 21 February 1804 with the first recorded steam-hauled journey on rails. The key personalities were the talented Cornish engineer Richard Trevithick and Samuel Homfray, owner of the Penydarren Iron Works.

The forges and rolling mills at Penydarren Iron Works, with the blast furnaces in the left background. In front of the buildings at the right is a horse pulling three loads of bar iron at the start of the journey to Abercynon where it would be transferred onto a boat on the Glamorganshire Canal for transport to Cardiff and loading onto a ship. It was just such a consignment of iron that Trevithick’s locomotive successfully transported. Etching by John George Wood for his book “The Principal Rivers of Wales”, 1812.

The pioneering locomotive was designed and built at Penydarren Iron Works over the winter of 1803-04.

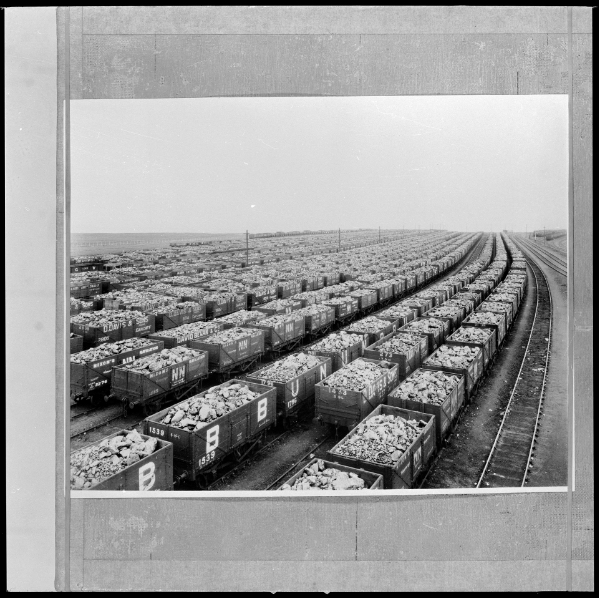

The locomotive successfully pulled five wagons loaded with ten tons of iron and 70 men who had hitched a ride on the wagons for the 9¾ mile journey. Over the following weeks the locomotive made a number of further journeys the length of the tramroad.

The locomotive was widely reported at home and abroad.

Frequent breakages of the brittle cast iron track by the unsprung locomotive resulted in it being converted into a stationary engine within a few months. Two further Trevithick-designed locomotives were built in England in 1805 and 1808 but he found no commercial backers.

“The Miners’ Express”, Saundersfoot Railway, 1900s. This primitive service harked back to early 19th century practices and may capture something of the atmosphere of the Penydarren locomotive’s trial run in 1804 when 70 men hitched a ride on the five wagons. This Saundersfoot Railway service was introduced in 1900 to enable coal miners from Kilgetty to travel to Bonville’s Court Colliery. The ironic name was created by the postcard publisher.

In 25 years steam-haulage had progressed from experimental to reliable. Within a few decades more, railways employing steam locomotives were in use on every continent.

The conjectural reconstruction of the Penydarren locomotive on display in the Networks gallery at the National Waterfront Museum at Swansea.

You may also be interested in this short film about Richard Trevithicks Steam Locomotive:

https://museum.wales/articles/2008-12-15/Richard-Trevithicks-steam-locomotive