Clogmaker’s Workshop

39

What is this building?

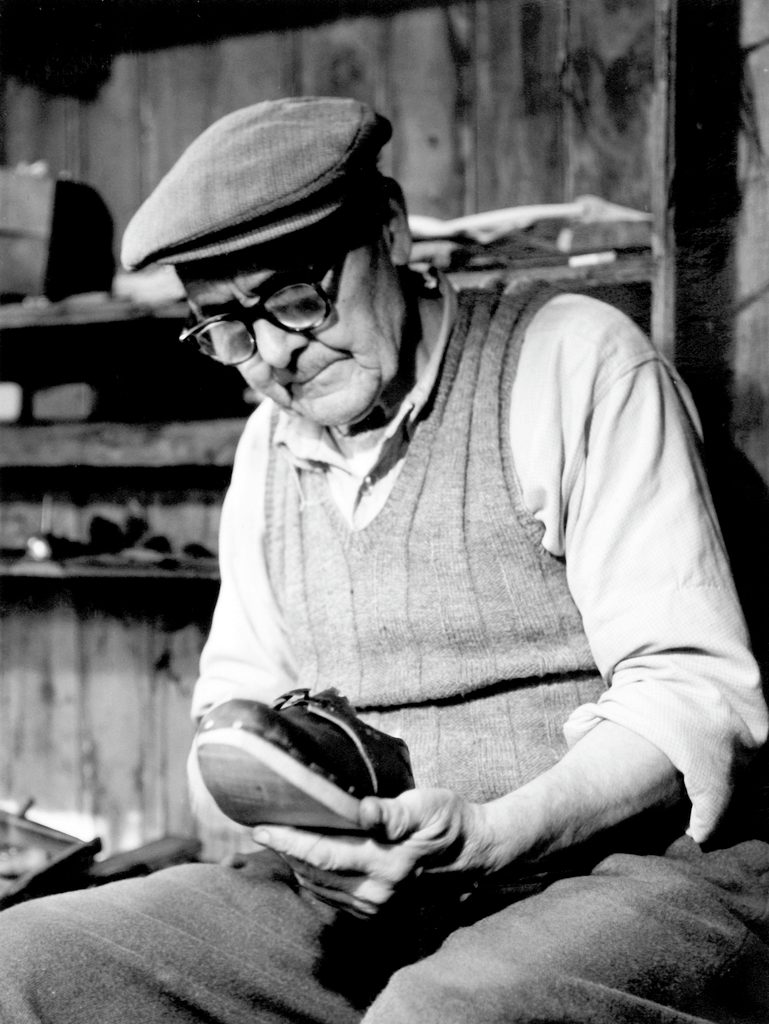

This is a clogmaker’s workshop. It originally belonged to Tommy James who was one of the last traditional clogmakers in Wales. Tommy trained as an apprentice for five years to learn the craft of clogmaking. It took him another two years to build and develop the skill.

His first workshop was near his family home in Croesgoch before moving to Ysgeifiog, near St Davids. He enlarged the building as the demand for clogs increased. His clogs were particularly popular with farmworkers who thought they were stronger than wellington boots. They protected their feet from accidents with agricultural equipment. Wood is a natural insulator and so kept the workers’ feet cool in the summer and warm in the winter, hence the term ‘clever clogs’!

How did Tommy make clogs?

Tommy would make clogs using wood from the sycamore tree for their soles. This wood is light in colour, hard and strong which makes it ideal for carving.

He used cow hide to make the upper parts. This is strong, thick leather called wax kip and, when heated, was flexible enough to be moulded into the shape of a clog.

The tools Tommy used were a stock knife to shape the wood into a shoe sole, the hollower which hollows where the foot sits and the gripper which cuts the groove (or rebate) into which the leather upper is nailed. Clogs are never made with flat soles thus enabling the wearer to ‘rock’ slightly when walking. A clicker knife and an edger were used to cut the leather.

Welsh and English clogs have always been made in this way unlike Dutch clogs (klompen) are all wood and made from poplar. Welsh clogs are also far more comfortable.

Today, Geraint the Museum’s clogmaker, one of only two in Britain, continues to make clogs in the same traditional way.

Geraint starts by measuring both feet of a person as everyone has one foot slightly bigger than the other and, like Tommy, uses wood and leather to make them. The whole process takes about 6 months. Geraint himself also wears clogs he made himself to work as they are so comfortable!

A finished pair of clogs

Did you know?

People once used sycamore to make furniture and kitchenware, such as ladles and wooden spoons. The reason for this is that the wood does not taint or stain the food as it has very little tannin and doesn’t warp when wet.

Another word for clog is ‘sabot’, as used in France and Belgium. The word ‘sabotage’ is derived from industrial disputes when workers who wore sabots as protective gear would throw them into the machinery.

Sometimes people talk informally about a person ‘popping one’s clogs’ when they die. Why is this used? The word ‘pop’ is another term for ‘pawn’. If a person knew they were dying they would ‘pop their clogs’. Similarly, when a person died, their relatives would ‘pop the clogs’ of the deceased.

Industrial workers, particularly in 19th century Lancashire cotton mills, once wore clogs for safety and comfort. The workers’ movements as they went about their daily jobs influenced the ‘heel and toe’ movements which form the basis of clog dancing.

Here in Wales there are folk dancing teams and their members wear clogs.